|

| Image: US Dept of Agriculture |

One thing is certain: Broiler chicken production is a business for professionals. With advances in breeding, feeding and animal husbandry, no other livestock species has been optimised as much as the modern breeds of broiler chicken. The key to successfully maximising growth performance is a well-developed intestine.

PreAcid is required across the entire digestive tract

Butyric acid and its salts, the butyrates, are important building blocks for the healthy development of the intestine. They support the development of intestinal villi and are therefore needed along the entire digestive tract. Butyric acid and its salts are metabolised at the start of the intestinal tract, where they become available to epithelial cells as a source of energy. In contrast, gluconic acid and its salts are not broken down until they reach the final section of the intestinal tract (Asano et al 1997), where they undergo bacterial fermentation that primarily generates butyrate (Kameue et al 2004; Tsukahara et al 2002).

As butyrate is also the main source of energy for epithelial cells of the large intestine (Roediger 1980), feeding gluconic acid and its salts can indirectly stimulate epithelial growth in the final section of the intestinal tract as well. This favours the development of a healthy intestinal structure (Biagi et al 2006). The combination of butyrate and gluconate therefore delivers an optimal supply of energy for epithelial cells along the entire intestinal tract, with the known advantages.

Studies have shown that gluconic acid can also stimulate the growth of useful microorganisms, such as for example bifidobacteria (Asano et al 1994; Tomioka et al 2001). An increased concentration of bifidobacteria in the intestine has a beneficial effect on the host organism's health and reduces the risk of diarrhoea (Picard et al 2005).

Proven in practice: PreAcid is reliable

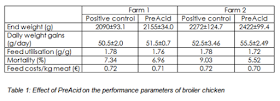

A series of tests carried out at two large broiler farms examined the effects of PreAcid on biological performance parameters and on the profitability of these businesses. To this end, the animals at Farm 1 (n=135,300) and Farm 2 (n=103,400) were divided into two feeding groups at each farm. The feed for the positive-control group contained butyric acid in capsule form, while that for the experimental group contained PreAcid.

PreAcid results: higher profitability

Following the analysis of eight sequential cycles, the outcomes in the PreAcid group were clear cut:

By using PreAcid, the production costs in both broiler factory farms could be reduced and notably higher dressing percentages achieved.

A positive side effect: As substantially lower odour levels arise during processing, handling PreAcid is clearly more pleasant compared with the use of butyrates.

For questions on cost-effective broiler production and the use of PreAcid, contact:

Daniela Martin

Technical Sales

Email: d.martin@dr-eckel.de

Tel.: 02636-9749-47

PreAcid is required across the entire digestive tract

Butyric acid and its salts, the butyrates, are important building blocks for the healthy development of the intestine. They support the development of intestinal villi and are therefore needed along the entire digestive tract. Butyric acid and its salts are metabolised at the start of the intestinal tract, where they become available to epithelial cells as a source of energy. In contrast, gluconic acid and its salts are not broken down until they reach the final section of the intestinal tract (Asano et al 1997), where they undergo bacterial fermentation that primarily generates butyrate (Kameue et al 2004; Tsukahara et al 2002).

As butyrate is also the main source of energy for epithelial cells of the large intestine (Roediger 1980), feeding gluconic acid and its salts can indirectly stimulate epithelial growth in the final section of the intestinal tract as well. This favours the development of a healthy intestinal structure (Biagi et al 2006). The combination of butyrate and gluconate therefore delivers an optimal supply of energy for epithelial cells along the entire intestinal tract, with the known advantages.

Studies have shown that gluconic acid can also stimulate the growth of useful microorganisms, such as for example bifidobacteria (Asano et al 1994; Tomioka et al 2001). An increased concentration of bifidobacteria in the intestine has a beneficial effect on the host organism's health and reduces the risk of diarrhoea (Picard et al 2005).

Proven in practice: PreAcid is reliable

A series of tests carried out at two large broiler farms examined the effects of PreAcid on biological performance parameters and on the profitability of these businesses. To this end, the animals at Farm 1 (n=135,300) and Farm 2 (n=103,400) were divided into two feeding groups at each farm. The feed for the positive-control group contained butyric acid in capsule form, while that for the experimental group contained PreAcid.

PreAcid results: higher profitability

Following the analysis of eight sequential cycles, the outcomes in the PreAcid group were clear cut:

- reductions in mortality up to 39 percent

- increases in end weights up to 6 percent

- increases in daily weight gains up to 5.7 percent

By using PreAcid, the production costs in both broiler factory farms could be reduced and notably higher dressing percentages achieved.

A positive side effect: As substantially lower odour levels arise during processing, handling PreAcid is clearly more pleasant compared with the use of butyrates.

For questions on cost-effective broiler production and the use of PreAcid, contact:

Daniela Martin

Technical Sales

Email: d.martin@dr-eckel.de

Tel.: 02636-9749-47

Visit the Dr Eckel site HERE.

The Global Miller

This blog is maintained by The Global Miller staff and is supported by the magazine GFMT

which is published by Perendale Publishers Limited.

For additional daily news from milling around the world: global-milling.com

No comments:

Post a Comment