The Marriage family have been flour millers in Essex since 1824 and farmers in the local area since the seventeenth century

by Roger Gilbert and Olivia Holden, Milling and Grain magazine

First published in Milling and Grain, March 2015

UK Essex farmers William and Henry Marriage diversified their 17th Century farming operations in 1824 by installing a mill to process grain, with some branny co-product being used as fodder for the farm animals. That was the starting point for one of today’s oldest UK milling operations.

Since then, William’s side of the family has been the flour millers, while Henry’s descendants continued to farm the land.

In the 1970s, compound feed was added to the manufacturing facility by Peter Marriage and he continues to run this today with cousin James, a sixth generation descendant of Henry Marriage.

The board of directors has always contained between three and six family members. There are currently three directors from the sixth generation and three from the fifth.

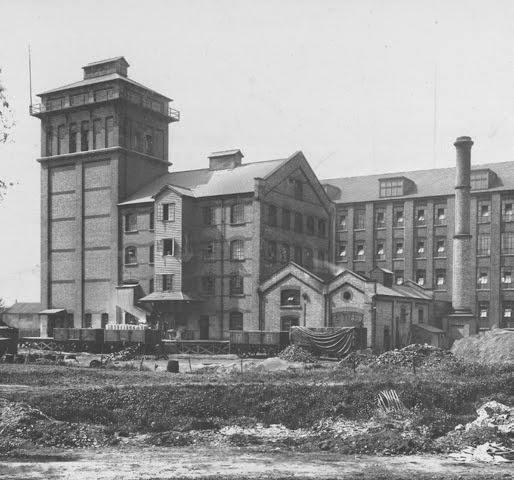

115 years ago the mill moved from outside Chelmsford - where it had been located for wind power and access to water - into the town itself and started to use mechanical power. Distribution also became more of a factor when competing with other flour millers.

The railway running through Chelmsford provided the company with easy access to the markets of Norwich, Ipswich and London, and eventually proved useful for raw materials coming in from overseas. The mill remains in the same location today, despite the conversion of other local factories into apartments, most notably that of Marconi, the builder of the first radio.

Future developments suggest that it will become ever more important to be close to the road network, as road haulage is now the only form of transport in and out.

Most recently the company has bought a pet food production plant in Driby, Lincolnshire, to complement the output in Essex.

“Our commercial poultry and livestock feed production is all done here in Chelmsford,” says James.

“The Driby site specialises in coarse mixing of bird food and small animal feeds, amongst other light processing.”

“Chelmer Mills has a strong reputation for making starter diets for poultry. We have a number of other niche areas, such as medicated, organic and non-GM feeds.”

“Organic output has waned in the UK in recent years, despite some support around Europe, particularly in Germany, where the ‘BIO’ or non-GMO movement is strongly supported. South American countries now take some persuading to produce organic or even non-GM soya.”

“We are proud of the traceability and reliability of our products.”

“We also make absolutely sure that the service is there, which retains customers in a competitive marketplace.”

Having the flourmill on site provides essential high quality co-products, such as the wheatfeed used in the feed mill. Retailers will also buy bran alongside compound feeds.

Wheatfeed produced during the roller milling of white flour is sold to pig farms where it is milled and mixed on-farm.

Local farms, including the family’s own 2000 acres to the west of Chelmsford, provide feed wheat, oats, barley, peas and beans direct to the mill.

“The cover we carry is about a month and a half, which may be extended if the futures markets are low.”

The mill imports fishmeal and soya, the former providing an exceptional and often essential form of protein.

Emphasis on poultry feed

“In recent years the feed mill has been producing up to 35,000 tonnes,” says James.

The emphasis is on poultry feeds, mainly layer hen, duck and turkey, which together make up almost 90 percent of production.

The are now ever fewer pig and dairy farms in the area and this has partly driven the change. The company does like to have a speciality like poultry but also wishes to retain an interest in all areas of agriculture. Being a relatively small feed mill and having its own transport has led to the company providing excellent service to the small farms in the area.

Compliance and accreditation

Accreditation and compliance become more important every year. The site has to accommodate up to 10 independent audits per year from various customer- and organisation-based services.

“These audits are taken very seriously and prepared for with a technical team, specific related procedures and processes and internal audits”.

In addition to this the company has a third-party pest controller who specialises in wheat mills and food stores.

Staff

Chelmer Mills has approximately 100 staff at any one time: 40 in the two mills, 20-30 in the transport department and 40 in the office, including sales teams.

Read the magazine HERE.

by Roger Gilbert and Olivia Holden, Milling and Grain magazine

First published in Milling and Grain, March 2015

UK Essex farmers William and Henry Marriage diversified their 17th Century farming operations in 1824 by installing a mill to process grain, with some branny co-product being used as fodder for the farm animals. That was the starting point for one of today’s oldest UK milling operations.

Since then, William’s side of the family has been the flour millers, while Henry’s descendants continued to farm the land.

In the 1970s, compound feed was added to the manufacturing facility by Peter Marriage and he continues to run this today with cousin James, a sixth generation descendant of Henry Marriage.

The board of directors has always contained between three and six family members. There are currently three directors from the sixth generation and three from the fifth.

115 years ago the mill moved from outside Chelmsford - where it had been located for wind power and access to water - into the town itself and started to use mechanical power. Distribution also became more of a factor when competing with other flour millers.

The railway running through Chelmsford provided the company with easy access to the markets of Norwich, Ipswich and London, and eventually proved useful for raw materials coming in from overseas. The mill remains in the same location today, despite the conversion of other local factories into apartments, most notably that of Marconi, the builder of the first radio.

Future developments suggest that it will become ever more important to be close to the road network, as road haulage is now the only form of transport in and out.

Most recently the company has bought a pet food production plant in Driby, Lincolnshire, to complement the output in Essex.

“Our commercial poultry and livestock feed production is all done here in Chelmsford,” says James.

“The Driby site specialises in coarse mixing of bird food and small animal feeds, amongst other light processing.”

“Chelmer Mills has a strong reputation for making starter diets for poultry. We have a number of other niche areas, such as medicated, organic and non-GM feeds.”

“Organic output has waned in the UK in recent years, despite some support around Europe, particularly in Germany, where the ‘BIO’ or non-GMO movement is strongly supported. South American countries now take some persuading to produce organic or even non-GM soya.”

“We are proud of the traceability and reliability of our products.”

“We also make absolutely sure that the service is there, which retains customers in a competitive marketplace.”

Having the flourmill on site provides essential high quality co-products, such as the wheatfeed used in the feed mill. Retailers will also buy bran alongside compound feeds.

Wheatfeed produced during the roller milling of white flour is sold to pig farms where it is milled and mixed on-farm.

Local farms, including the family’s own 2000 acres to the west of Chelmsford, provide feed wheat, oats, barley, peas and beans direct to the mill.

“The cover we carry is about a month and a half, which may be extended if the futures markets are low.”

The mill imports fishmeal and soya, the former providing an exceptional and often essential form of protein.

Emphasis on poultry feed

“In recent years the feed mill has been producing up to 35,000 tonnes,” says James.

The emphasis is on poultry feeds, mainly layer hen, duck and turkey, which together make up almost 90 percent of production.

The are now ever fewer pig and dairy farms in the area and this has partly driven the change. The company does like to have a speciality like poultry but also wishes to retain an interest in all areas of agriculture. Being a relatively small feed mill and having its own transport has led to the company providing excellent service to the small farms in the area.

Compliance and accreditation

Accreditation and compliance become more important every year. The site has to accommodate up to 10 independent audits per year from various customer- and organisation-based services.

“These audits are taken very seriously and prepared for with a technical team, specific related procedures and processes and internal audits”.

In addition to this the company has a third-party pest controller who specialises in wheat mills and food stores.

Staff

Chelmer Mills has approximately 100 staff at any one time: 40 in the two mills, 20-30 in the transport department and 40 in the office, including sales teams.

Read the magazine HERE.

The Global Miller

This blog is maintained by The Global Miller staff and is supported by the magazine GFMT

which is published by Perendale Publishers Limited.

For additional daily news from milling around the world: global-milling.com

No comments:

Post a Comment