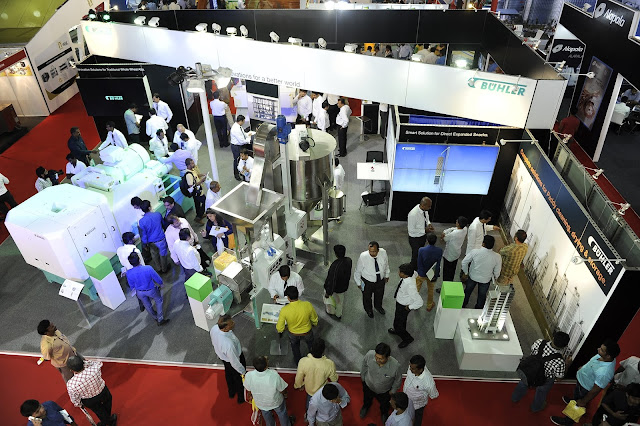

The Bühler Group, a global leader in grain processing equipment and food processing machines, participated in the 6th Edition of GrainTech 2015 at the Bengaluru International Exhibition Centre (BIEC), Bangalore, India. The company had a large stall, measuring 120 square metres, with a wide range of new products on display for the food processing industry.

Products such as the PesaMill™ - a new innovative solution for the Atta Milling process -, the SmartSnax™ single-screw extruder, YJT W DualVision™ optical colour sorters, the RollDetect service for profile measurement of corrugated (fluted) rolls, the NIR Multi online analyser for real time analysis of raw material and finished product, the online colour and speck measurement unit for continuous online checking of product colour and specks in flour and semolina, and online particle size measurement.

Bühler’s Atta process with PesaMill™ is the first industrial process technology for the production of Atta flour with a completely authentic taste under perfect hygienic conditions. With this fully integrated all-round process, just one PesaMill™ can replace as many as twenty traditional chakki mills – with a whole load of further advantages: higher yield, reduced energy consumption and the possibility of producing several types of flour qualities in the same plant.

Thanks to effective, integrated and energy-efficient process technology, by using one PesaMill™ rather than a lot of isolated traditional stone mills you can save up to 10 percent of the energy costs.

Greater flexibility in production

PesaMill™ provides the basis for flexibly adjusting the properties of the flour to individual requirements. Starch damage, water absorption and granulation can be simply and swiftly adjusted for different types of flour qualities (eg North Indian Atta, South Indian Atta etc.).

Maximum food safety

The use of high-compression steel rolls rather than stones for milling means that hygiene standards are very much higher. Contamination by stone abrasion or chemicals becomes a thing of the past.

Protected investments

Thanks to innovative technology and a robust design backed up by the highest standards of manufacturing quality, the Bühler Atta process with PesaMill™ guarantees a long service life and the best possible protection for your investment.

Reduced operating costs

In traditional stone mills, the millstones need to be redressed or replaced frequently. Not so the PesaMill™. Hence downtimes are minimised, productivity is raised and the system can operate reliably 24/7. Following a power outage, the machine can resume operations immediately – without any loss of product quality.

The advantages of the Atta process with PesaMill™:

- Higher yield

- Reduced energy consumption

- Improved food safety

- More flexible production processes

- Less maintenance required

- Lower operating costs

The process expertise for direct expanded snacks by single-screw extrusion is now available in India. Bühler’s expanded (DX) snack processing solutions present an effective, reliable, safe and operator-friendly system for snack processing of the highest quality and suitable to local needs and tastes.

Advantages:

- Food-safe design

- Wear- and corrosion-resistant working elements - screw, barrel and dies

- Easy and intuitive operation

- Easy controls

Bühler's YJT W DualVision Color sorter offers simultaneous light and dark

sorting on up to 7 chutes for high processing capacities. The YJT W DualVision

is targeted to give processors of pulses, spices and sesame seeds advanced

performance at an affordable price.

When combined with LED lighting, this optical sorter

improves the level of sorting performance, provides better plant efficiency,

and saves on manpower costs.

The YJT W DualVision is the natural choice for processors of

pulses, spices and sesame seeds who are looking for stable and consistent high

performance, with the flexibility for multi-product sorting at an affordable

price.

Advantages:

- Simultaneous light and dark sorting

- Flexibility for multiple products

- High capacity and consistent product quality

- Trusted Bühler design and reliability

- Balanced and stable performance

RollDetect Service

The RollDetect service informs the operator on the optimal

time to change grinding rolls. Currently, knowing when to change corrugated

rolls is determined based on the flour miller’s experience and intuition. The

innovative RollDetect measuring unit enables the corrugation profile to be

graphically displayed and its wear to be evaluated. This provides the head

miller with data that can be combined with experience. The timing for roll

changes determined by RollDetect is key to achieving a high product yield and

reducing operating costs.

Benefits:

- Energy savings

- Optimisation of product yield

- Potential for precise planning of roll changes

NIR Multi online Analyser – MYRG

Real time analysis of the raw material and end product at

different measuring points, allowing smart and continuous control of ongoing

production – this is the true strength of the NIR Multi online Analyser MYRG.

With the latest Bühler NIR generation, one spectrometer evaluates up to 6

different measuring points.

The NIR Multi Online Analyser MYRG is distinguished by its

durability and reliability. Only the measurement probe is located in the

production environment. The control cabinet provides ideal protection of the

optical and electronic components.

The scope of supply of the NIR Multi Online Analyser

includes pre-calibrated applications such as protein, moisture, ash content,

starch damage, wet gluten and water absorption.

Main benefits:

- Reliable and reproducible measurement results

- Hardware is not affected by dust, temperature nor vibrations

- Compact and flexible installation, e.g. directly on the gravity spouting

Online colour and speck measurement unit – MYHB

The unit allows continuous online checking of the product

color and specks in ongoing flour and semolina production. It thus ensures

early detection of even the subtlest colour deviations, contamination and sieve

ruptures so as to ensure top product quality. The probe and its results can be

combined with those from Multi NIR online Analyser MYRG at any time.

Main benefits:

- Reproducible product quality

- Continuous monitoring of colour and specks

- Reduced lab testing requirements

- Traceability of production due to complete documentation

Online particle size measurement – MYTA: Real-time granulation measurement

Whether during the various grinding processes of a flour

mill or while monitoring the material being ground on a hammer mill. The exact

knowledge if the particle size distribution is crucial for the quality and

consistency of the end product.

This measurement system is suitable for continuous particle

size measurement (PSM) in the range of 10 – 5000 microns. The online PSM

combines laser diffraction and image processing in a system capable of

determining the particle size distribution of the ground material during an

ongoing process.

Main benefits:

- Real-time monitoring of grinding processes and product granulation

- Finished products with a consistent particle size distribution

- Measurement results are directly comparable to the traditional sieve method

- Detection of oversize processes

The Global Miller

This blog is maintained by The Global Miller staff and is supported by the magazine GFMT

which is published by Perendale Publishers Limited.

For additional daily news from milling around the world: global-milling.com

No comments:

Post a Comment