by Jenny Nielson Christensen, MBA, Vice President of Marketing, BinMaster

First published in Milling and Grain, April 2016

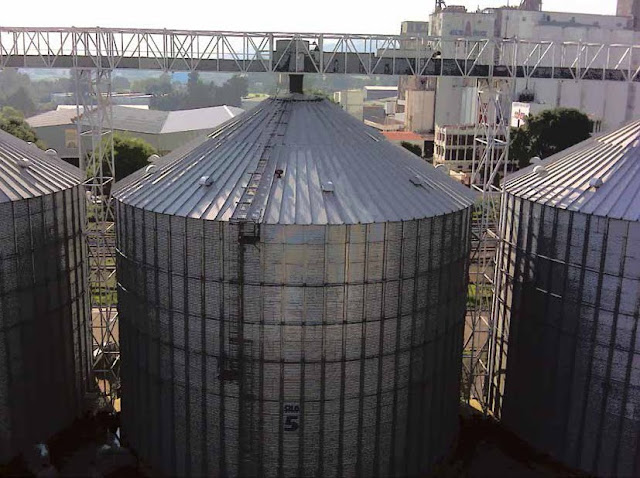

Bin level indicators have been around for decades. From simple switches and rotaries, to advanced noncontact sensors, there’s no shortage of technologies to choose from. But there’s more to bin levels than just the sensor.

Today’s grain and milling operations are increasingly automated with more sophisticated and complex systems. Plus, with increased consolidation and a global grain economy the needs of the industry have changed … and manufacturers of bin level indicators have responded with new solutions to address those demands.

The good news is if your operation is small or large, has one bin or hundreds, has a single location or a global presence, there is a solution for you. The solution starts by determining your sensor needs and applying the right sensor for the material and vessel.

Then, comes another set of considerations: Once you have all this data, how do you get it from your bins to where you need it, and what do you do with it when it gets there? Here are some things to ask of your operation:

First published in Milling and Grain, April 2016

Bin level indicators have been around for decades. From simple switches and rotaries, to advanced noncontact sensors, there’s no shortage of technologies to choose from. But there’s more to bin levels than just the sensor.

Today’s grain and milling operations are increasingly automated with more sophisticated and complex systems. Plus, with increased consolidation and a global grain economy the needs of the industry have changed … and manufacturers of bin level indicators have responded with new solutions to address those demands.

The good news is if your operation is small or large, has one bin or hundreds, has a single location or a global presence, there is a solution for you. The solution starts by determining your sensor needs and applying the right sensor for the material and vessel.

Then, comes another set of considerations: Once you have all this data, how do you get it from your bins to where you need it, and what do you do with it when it gets there? Here are some things to ask of your operation:

- Do you want point level alerts or inventory management?

- Is the data needed locally or at multiple locations?

- Do you need the ability to run reports?

- Where do you want your data stored?

- How long do you want to keep historical data?

- Who has access to the data? Does everyone have the same access?

- Does your data need to be secure or kept confidential?

- Do you want alerts for low or high level thresholds?

- Is mobile access to the data needed?

The Global Miller

This blog is maintained by The Global Miller staff and is supported by the magazine GFMT

which is published by Perendale Publishers Limited.

For additional daily news from milling around the world: global-milling.com

No comments:

Post a Comment