by Mildred Cookson, The Mills Archive, UK

First published in Milling and Grain, May 2016

As with my last article, I have chosen accounts from The Miller and Milling describing the same mill a few years apart at the start of the 20th century. These two Victorian publications, but with some significant gaps, are held at the Mills Archive.

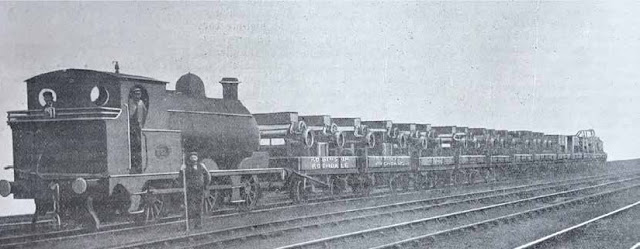

On 7 August 1899, The Miller reported on a visit to the North Shore Milling Company in Liverpool, run by Mill Manager Mr Edward Cooper and his assistant Mr John Westgate. The firm was established on Boundary Street in 1848 before any other flour-mill of this type had been installed in Liverpool. It was capable of 100 sacks (280lbs) per hour and was divided into three separate and distinct plants, all under the same roof.

Along with new silos, the flour and offal warehouses, grain cleaning plant and workshops for millwrights and carpenters, the whole operation occupied a total ground area of 11,000 square yards. There were also cellars beneath the buildings and the mill yard, with a central warehouse used to store grain and the mill products.

The mill was powered by a triple expansion engine, put in during 1895 by Messrs Yates and Thorn of Blackburn and was capable of exerting 1,400 imperial horsepower, the initial steam pressure being 200psi and on the second cylinder about 80psi. In 1898 Thomas Robinson put in new silos, fully equipped with conveyors, elevators and separators.

By 1899 the mill had seven Haggenmacher plansifters manufactured by Whitmore & Binyon in place. The large-scale grain cleaning department had machines for separating, aspirating, grading, seed extraction, washing, stoning, whizzing, conditioning and scouring and during 1899, they were putting in new machines to improve the condition of the wheat passing to the mill.

Read the full article in Milling and Grain HERE.

First published in Milling and Grain, May 2016

As with my last article, I have chosen accounts from The Miller and Milling describing the same mill a few years apart at the start of the 20th century. These two Victorian publications, but with some significant gaps, are held at the Mills Archive.

On 7 August 1899, The Miller reported on a visit to the North Shore Milling Company in Liverpool, run by Mill Manager Mr Edward Cooper and his assistant Mr John Westgate. The firm was established on Boundary Street in 1848 before any other flour-mill of this type had been installed in Liverpool. It was capable of 100 sacks (280lbs) per hour and was divided into three separate and distinct plants, all under the same roof.

Along with new silos, the flour and offal warehouses, grain cleaning plant and workshops for millwrights and carpenters, the whole operation occupied a total ground area of 11,000 square yards. There were also cellars beneath the buildings and the mill yard, with a central warehouse used to store grain and the mill products.

The mill was powered by a triple expansion engine, put in during 1895 by Messrs Yates and Thorn of Blackburn and was capable of exerting 1,400 imperial horsepower, the initial steam pressure being 200psi and on the second cylinder about 80psi. In 1898 Thomas Robinson put in new silos, fully equipped with conveyors, elevators and separators.

By 1899 the mill had seven Haggenmacher plansifters manufactured by Whitmore & Binyon in place. The large-scale grain cleaning department had machines for separating, aspirating, grading, seed extraction, washing, stoning, whizzing, conditioning and scouring and during 1899, they were putting in new machines to improve the condition of the wheat passing to the mill.

Read the full article in Milling and Grain HERE.

The Global Miller

This blog is maintained by The Global Miller staff and is supported by the magazine GFMT

which is published by Perendale Publishers Limited.

For additional daily news from milling around the world: global-milling.com

No comments:

Post a Comment