In the last two years 15 million Africans - and perhaps as many as 82 million - have gained access to more nutrition in their staple foods due to increased amounts of wheat flour being fortified with essential vitamins and minerals, according to estimates by the Flour Fortification Initiative (FFI). The Africa assessment was a highlight of the FFI executive management team (EMT) meeting in Atlanta April 16-17, 2013.

“Fifteen million is a very conservative estimate as it only includes people living in urban areas,” said Scott Montgomery, FFI director. “The combined population of countries in Africa where flour fortification is standard milling practice now is 443 million. In 2011, it was 361 million. The health benefits of food made with fortified flour are probably reaching somewhere between an additional 15 million and 82 million people now than in 2011.”

Cargill Inc. has confirmed that four workers died at its grain delivery facility in Canarana, Brazil, when a silo containing soybeans collapsed.

The four killed, one employee and three contractors, were trying to release soybeans stuck inside a metal silo when it collapsed and stored grain fell. The four bodies have been located.

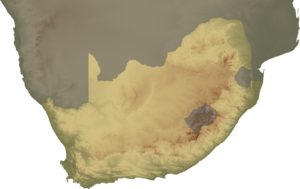

The ROFF R70, launched April 17, 2013 on the farm Sardinia of Mr Flippie Blignaut, is arguably South Africa’s most cost-effective, compact four ton per hour mill. The first R70 mill installed in South Africa. ROFF has already installed two of these mills in Zimbabwe to ensure more affordable food staples for the public by reducing supply chain and distribution costs.

As a successful business built through hard work, innovative thinking and the agility to adapt to changes in the marketplace, Mr Blignaut’s farm provided the ideal backdrop for the South African launch of the versatile R70.

Sardinia Milling was established 13 years ago to add value to the primary crop,

maize. A combined farming model ensures optimised efficiency and an increased profit margin. Maize is produced, stored in silos on site, high quality endosperm is extracted and marketed as top- notch meal, and maize bran – a by-product of the milling process – is used as base for the animal feed provided to cattle feeding schemes.

As such, maize only leaves the farm in the form of meal and livestock. This model shortens the supply chain to ensure maximum profitability. The end-user also benefits, as a large percentage of the product is distributed within in a small radius, which keeps distribution costs to a minimum.

No comments:

Post a Comment